Proficy Plant Applications 2023 is out now!

With Proficy Plant Applications 2023, manuacturers can decrease downtime and improve operator performance through new capabilities for discrete, process and mixed manufacturing.

Click here, to find out more!

The functional breadth and depth of Proficy Plant Applications has made it the solution of choice for some of the world’s largest manufacturers. Able to handle mixed modes of manufacturing (batch, process, discrete), it ensures that users don’t have to compromise on capability or invest in overlapping solutions to get the results they need.

Plant Applications integrates well with data from sensors and automation (even where information at that layer is inconsistent!), so you can shift your operators’ focus from collecting data, to using it. And with a modern web-based interface for dashboards, reporting and activity management, you can ensure that the people in your plant have their work and supporting information at their fingertips.

A Modular Approach for Comprehensive Functionality

Recognising that manufacturers will often have a mix of systems in place, Plant Applications is offered in a series of modules. So you can supplement investments already made in plant systems and automation, rather than be forced into disruptive replacements or overlapping deployments. The modules are built on common core configurations used across the suite – so your first deployment helps create the foundation for the next module(s) you adopt.

Efficiency

Plant Applications Efficiency provides a complete Overall Equipment Effectiveness, (OEE) solution, including the details of the Quality, Performance and Availability scores. KPIs and details are available by order, production area/line/unit and even by-SKU. So operators and supervisors can quickly see what’s needed to keep things running smoothly. And your engineering, maintenance and improvement teams can spot the patterns that indicate the need for more intensive re-engineering of equipment, recipes or SOPs.

Quality

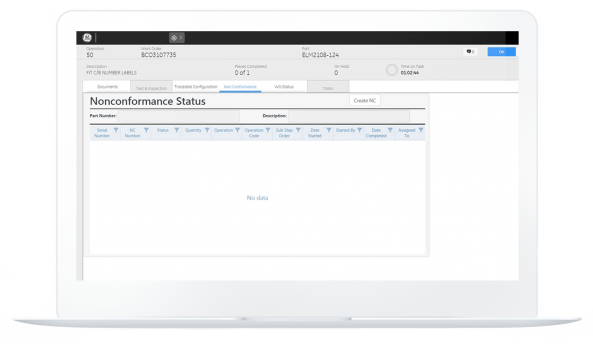

“You can’t test quality into a product”. With that in mind, Plant Applications lets you deploy specifications that address process stability/consistency, as well as material (raw, WIP or finished goods) characteristics. Taking advantage of Plant Applications’ integration with control systems and sensors, you can automatically monitor specifications and trigger alerts/disposition rules. So your teams can have the earliest possible chances to adjust processes and keep production on track. And for regulated environments, you can deploy user security and signoff capabilities that will support compliance with 21 CFR Part 11 regulations.

Production

The Production module provides the order management and WIP tracking backbone that enables coordination and execution. Plant Applications is particularly strong at managing production models involving complex, dynamic routes, and Bills of Material, and the need to follow parent/child or lot/sublot flows for track-and-trace purposes. And again, the flexibility of integrating machine data can automate the collection of production counts, inventory consumption, progress information and more. Production can be integrated with ERP and inventory systems to provide a closed-loop flow for order data, and the production actuals that drive supply chain operations and costing.

Batch Analysis

For operations making use of ISA-88 based batch execution systems, Plant Applications offers a library of batch throughput and quality analysis views. Speed up batch review/release procedures, or improve your quality and process analysis with tailored views of how your batches were run, and the related quality and process data.

Core Functionality

- Track orders and production, with supporting product, route, BOM and related information at hand

- Deploy quality and process specifications that allow for faster insight and reaction to process or quality deviations

- Deliver full OEE-based performance analysis to key stakeholders

- Integrate with PLC, DCS, sensor and SCADA data to automate data collection

- Digitise production activities and review/signoff procedures

- Manage production recipe setpoints and related information for transfer to automation systems

- Analyse machine data alongside manually captured information to manage exceptions and identify improvement opportunities

- Automate collection and integration of “actuals” data with your enterprise systems

One Solution for All Kinds of Manufacturing

Almost every manufacturing operation has multiple modes. A discrete manufacturer may have processes such as sintering, or annealing; the packaging operation in a food or drink plant has many similarities to repetitive discrete production. Plant Applications is uniquely able to manage all production and process models from a single platform. So you can achieve end-to-end tracking and performance analysis with a single manufacturing execution system.