What is SCADA?

SCADA, Supervisory Control and Data Acquisition, is an automation system for monitoring, control and management. The system monitors devices such as sensors, valves, pumps and motors, and provides an overview of events in the plant or factory.

The SCADA system came on the market in the 1960s, and is an important part of industrial digitalisation. Today, SCADA is among the most common types of industrial control systems, and is found in the vast majority of factories and plants.

With a SCADA system, you get the necessary overview to be able to make decisions that optimize production. An efficient system can provide significant savings in time and costs, among other things by reducing energy consumption and detecting faults on machines and equipment immediately.

The system consists of computers, web-based communication and a graphical user interface called HMI. At Novotek, we often use the term HMI/SCADA.

What is HMI?

HMI stands for Human Machine Interface, and is the term for the user interface between machine and human. In practice, this means a screen that presents information graphically for the operating personnel.

Monitoring, control and management of the factory or plant takes place via HMI, – for example a PC screen or tablet. Here, the operator gets an overview in real time, and can issue commands, adjust machine controls or change settings via mouse pointer, keyboard or touch screen.

Modern SCADA systems come with High Performance HMI object library. This provides an optimised user interface, without unnecessary elements, which means that the visual information can be interpreted more easily and quickly.

This is how an HMI/SCADA system works

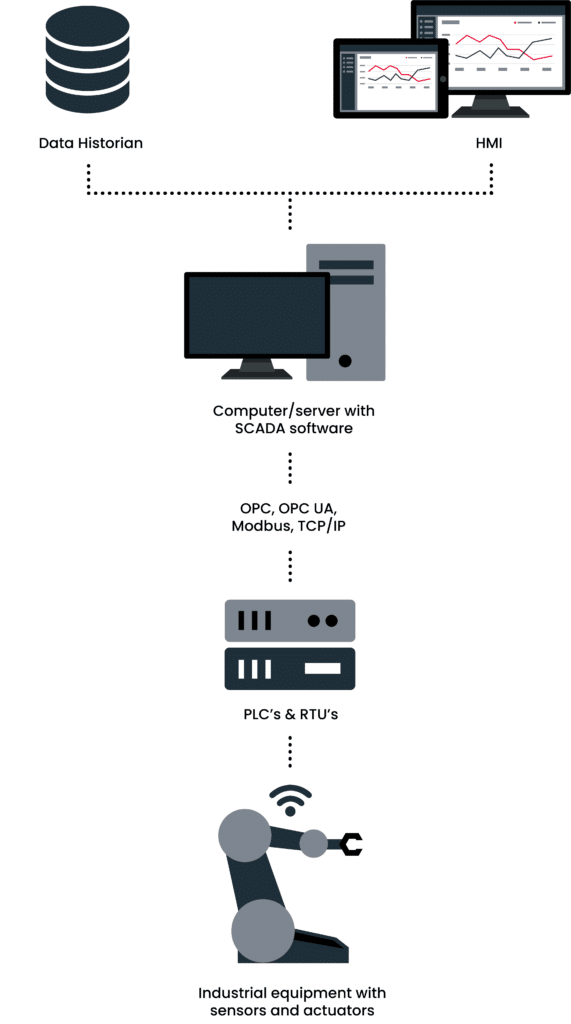

The system consists of four main elements:

Computer

The SCADA software runs on a computer. Here, process data is collected, and control commands are sent to connected devices.

PLC and RTU

PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units) are connected to sensors and actuators in the facility or factory, in addition to the parent computer.

Communication infrastructure

The communication infrastructure is what connects the computer to the PLCs and RTUs. Communication can be done via various protocols, including OPC, OPC UA, Modbus and TCP/IP.

HMI

The HMI is the user interface that presents the information to the operator. The HMI can be the same computer that the SCADA system runs on, an external PC, or tablet and mobile.

Integration with other technology

The SCADA system can be easily connected to other technology. It can be tightly integrated with a Historian database for collecting industrial data, and viewing and analysing it in context.

SCADA system in use

How does the system work in practice? Here is an example:

An operator is notified of errors in production. In the HMI he can see that the pump is running as it should, but the flow meter shows that too much liquid is being pumped through the pipe. Via the screen, he can switch off the pump temporarily, see the reduction in real time, and make the necessary settings to solve the problem.

With the help of the SCADA system, the operator could spend less time on navigation and find critical data faster. This ensured less downtime, reduced costs and more optimal operation.

Test yourself with the SCADA game!

Can you keep control of the SCADA system? Manage your water supply efficiently, avoid unplanned downtime, balance your electricity costs and keep the residents of Water Town happy.

-

Download file

SCADA for various industries

Today, SCADA systems are found in most facilities and factories. It is used in all types of industries, including:

Systems are adapted to industry-specific needs, as well as the individual needs of each facility or factory, and varies from simple setups to large complex systems.